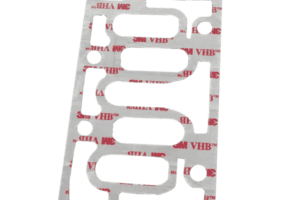

Precision Die Cut Gaskets for Every Application

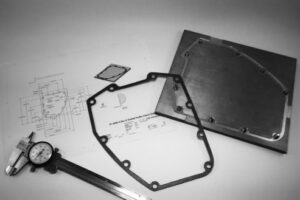

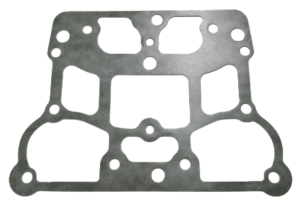

CGR Products delivers high-quality, custom die cut gaskets engineered to meet your exact specifications and demanding industry standards.

What Are Die Cut Gaskets?

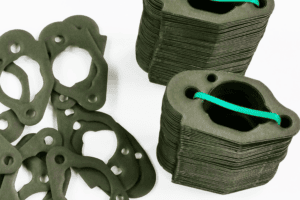

Die cutting is a highly efficient manufacturing process used to convert raw materials into custom shapes using a specialized press and a “die” (a sharp, custom-made blade). This method is ideal for producing gaskets and seals with consistent dimensions, tight tolerances, and high volumes.

At CGR Products, we leverage advanced die cutting technology to produce precision components for a vast array of industries, ensuring reliable sealing and performance in critical applications. Whether you need simple shapes or complex designs, die cutting offers a cost-effective and rapid solution.

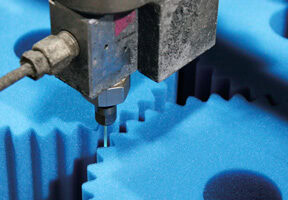

Our Advanced Die Cutting Capabilities

CGR Products utilizes a variety of die cutting methods to best suit your project’s volume, material, and tolerance requirements. Our expertise ensures optimal results, every time.