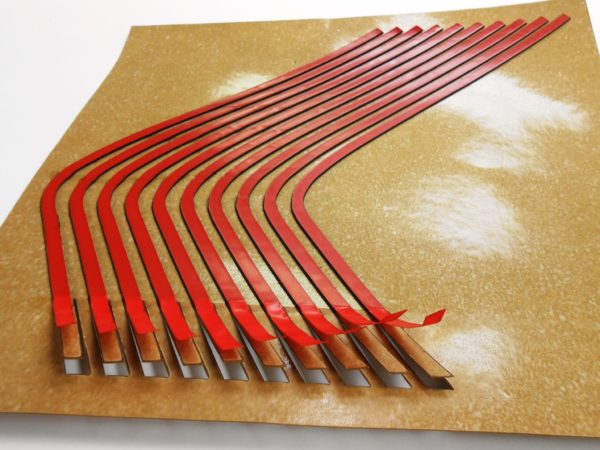

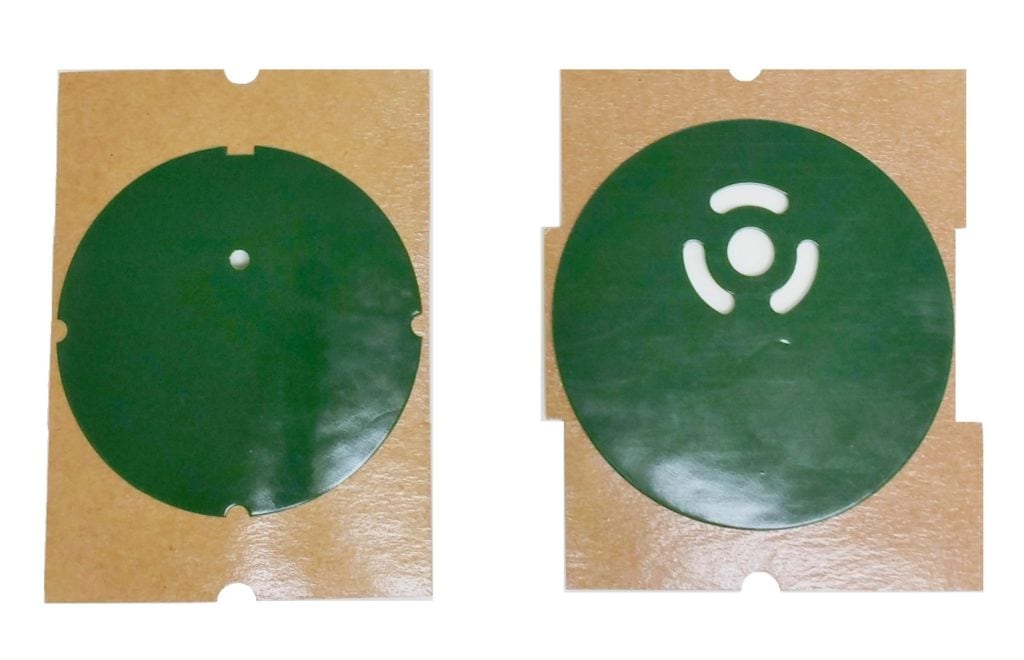

CGR offers tapes and adhesives for products across industries, including those that are exposed to extreme environments.

Tapes and adhesives often act as the bond that keeps the gasket or seal in place. Thus, careful attention must be paid to select the proper adhesive depending on intended use. Adhesives that strip or crack under exposure can create inefficiencies in an assembly, but more importantly, can compromise the safety of the surrounding area.

CGR Products is recognized by 3M™ as a leader in the converting industry and is acknowledged as a 3M™ Preferred Converter. We stock many 3M™ materials and have access to all materials available from the 3M™ converter markets as well as automotive tapes and adhesives and Thinsulate™. As a 3M™ Preferred Converter, CGR Products has immediate access to the newest materials and data provided by 3M™.

Our goal at CGR is to provide options when it comes to adhesives. Since there is an almost limitless combination of substrates and atmosphere conditions that require sealing, it is our duty to find products that perform in virtually any use across a spectrum of industries. Therefore, we offer adhesives that are pressure-sensitive and resistant to thermal and chemical conditions.

We also provide adhesives that are specifically designed for different substrate materials and end-use conditions whether they be low energy surfaces, powder coated, high and low temperature, or exposed to UV rays and weathering.

Our range of adhesives includes:

- Pressure-sensitive adhesives

- 3M VHB Tapes

- EMI Shielding Tape

- Dual-tack pressure sensitive adhesives

- Adhesive Transfer Tapes

- Double coated tapes with film, paper, tissue, or scrim carriers

Please view the table below for a complete list of tape and adhesive materials.

| Tapes & Adhesives | Description | Suppliers |

|---|---|---|

| Acrylic Pressure Sensitive Adhesives * Double Coated * Scrim Supported * Tissue Supported * Adhesive Transfer | Acrylic adhesive has a strong initial bond that improves over time and adheres well to many surfaces. They have excellent aging characteristics, outstanding chemical and ultra-violet light resistance, and higher temperature stability than rubber based adhesives. Acrylic pressure sensitive adhesives are optimal for long-term, durable applications. Double Coated Tapes: Tapes produced with adhesive on both sides of paper, film, or tissue. This increases the dimensional stability of the adhesive for easy handling and application. Adhesive Transfer Tapes: These are manufactured as rolls of pressure sensitive adhesive pre-applied to a special release liner. | 3M™ Adchem/Berry Applied Products Avery CCT MacTac |

| Acrylic Foam Tapes | Acrylic Foam Tapes are made with acrylic foam, providing outstanding strength and durability for highly demanding applications. The foam, which is viscoelastic in nature, utilizes energy-absorbing and stress-relaxing properties, which gives the tape its unique characteristics. The completely closed-cell foam tapes are used to bond applications with dynamic forces in exterior and extreme conditions. The degree of bond achieved allows VHB/AFT to replace non-tape fastening methods such as mechanical fasteners, liquid adhesives, and other permanent fasteners. | 3M™ Automotive AFT 3M™ Industrial VHB™ |

| Aluminum Foil Tapes | Foil Tapes resist flames, temperature extremes, high humidity, exposure to UV rays and most chemicals. | 3M ™ Avery |

| EMI Shielding Tape | EMI Shielding Tapes are designed for applications requiring reliable point-to-point electrical contact, particularly EMI/RFI shielding, grounding, and static charge draining. | 3M™ |

| Foam Tapes (Stripping) | Foam Tapes seal, cushion, dampen vibration, resist impact and withstand wide temperature ranges to bond to rough or irregular surfaces in permanent or repositionable applications. Commonly referred to as stripping or weatherstripping. | 3M™ Adchem/Berry CGR |

| Glue Web | Adhesive glue webs are nonwoven webs made of 100% thermoplastic adhesive polymer resins which are activated by heat and pressure. Glue web adhesives bond well to materials such as textiles, nonwovens, leather, foams, wood, films, metals, glass, carpet, and plastics. | SpunFab |

| Masking tape | A pressure sensitive tape made of a thin and easy-to-tear paper characterized by its ease of removal. Used in painting to mask-off areas that should not be coated. | 3M™ |

| Rubber Pressure Sensitive Adhesives | Rubber based pressure sensitive adhesives provide a wide range of adhesion, utilizing natural or synthetic materials mixed together to formulate a bond. These products bond well to low energy surfaces (polypropylene and polyethylene). The operating temperature range on these products is limited to 130 degrees F with intermittent temps up to 145 degrees F. Rubber PSAs have relatively poor resistance to weathering and may lose tack, discolor or become brittle over time. | 3M™ Adchem/Berry |

| Silicone Pressure Sensitive Adhesives | Silicone adhesive provides a good bond to silicone rubber, strong holding power to various silicone surfaces, good temperature performance and good solvent resistance. | 3M™ |

For more information about which of our adhesives is perfect for your substrate / conditions combination, please do not hesitate to contact us today. Together, we can find the perfect solution for your adhesive needs.