These are some of the success stories and case studies CGR Products has completed. Learn more about our full scale of materials, die cutting, laminating, and other converting capabilities.

Automotive Mirror Vibration

CGR Products has a history of providing creative solutions to our customer’s most difficult problems. This was exactly the case with a large truck cab manufacturer that was experiencing issues with squeaks and rattles from their newly designed side mirrors. The Problem Our initial meeting with the customer gave us the history of their issues….

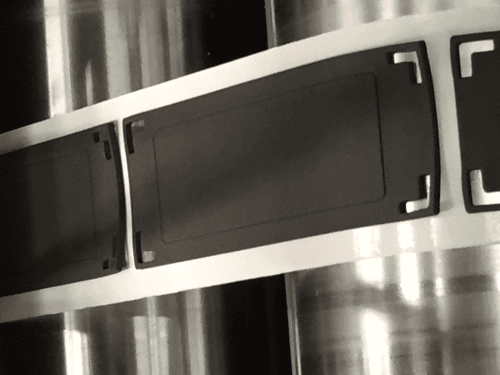

Die Cutting 3M Thinsulate™ with Tabs for Easy Installation

The usage of Recreational Vehicles is on the rise. The North American recreational vehicle (RV) market was valued at USD 33.95 billion in 2021 and is anticipated to reach USD 59.16 billion by 2027. Adding to this is a growing movement called “Van Life” When a custom camper van company came to CGR Products searching…

CGR Helps Solve Large Boat Manufacturers Sponge Stripping Issue

With a wide variety of materials and resources at our disposal, CGR always finds the correct solution for our customers in the automotive, marine, plastics, electrical, or another industry. Another one of our strengths is the ability to adapt, especially when our partners change an aspect of their project down the line. This was exactly the…

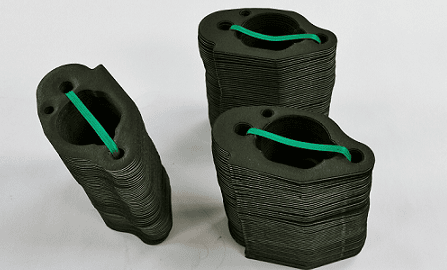

Turning a Badly Designed Gasket into a Usable Solution

One of our larger customers came to us with a new gasket to be cut from thin sponge rubber with adhesive. This part presented a challenge, since small cutouts were placed extremely close from the edge of the part. The part was to be cut individually, holes cleared and stacked in a box. In addition,…

Solving Tolerance Challenges with Our OEM Partner Program

After CGR acquired an existing fabrication business in Waukesha, WI in 2012, one of our primary goals was to establish a partnership with the company’s existing customer base. We had the opportunity to develop a strong relationship with one of the company’s clients while uncovering tolerance challenges in a number of their parts. The Challenge:…

Solving Performance Issues with a Custom Assembly Machine

The Challenge: New EPA regulations required a hose manufacturer to alter the construction of its assembly. Comprised of fuel line “Y” fittings, fuel filters, check valves, and spring steel hose clamps, each connection point on the assembly featured a variety of compression seals — some of which were offered by spring clips or various barb…

Solving a UL Gasketing Issue for a Large Enclosure Manufacturer

CGR Products has the resources to provide solutions for difficult problems. This was the case for a large enclosure manufacturer that was having an enclosure fail its UL certification for a seemingly simple issue. The Problem The enclosure manufacturer was using a standard closed cell sponge with adhesive on one side for sealing the door…

Solving a leak issue on General Motors Automobiles

When an automotive tier one supplier came to CGR Products with a leak issue around an injection molded module for gas pedals, we jumped to action by providing multiple prototypes to ultimately find the ideal solution. The Challenge: Our Initial meeting with the tier supplier gave us the history to their issues. Their customer, General…

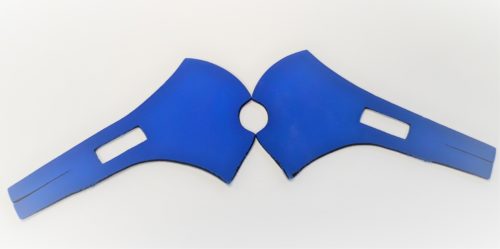

Solutions To Help Fight COVID-19

CGR Products is classified as an “essential business”. We die cut critical engineered parts that go to other essential businesses. The amount of inquires we’ve received has been both overwhelming and a blessing, including companies that range from major automotive manufactures making ventilators to high school students 3d printing face shields in their homes. Ventilators The ventilator…

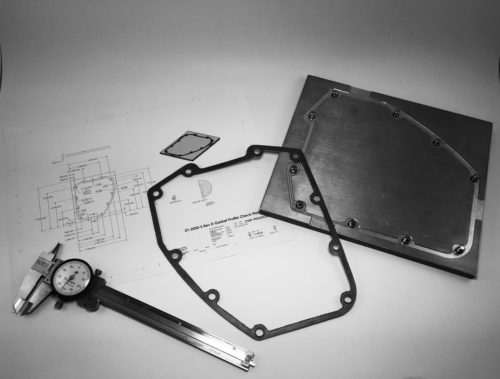

Solution for an Immediate Gasketing Need to Seal Escaping Steam.

We have a problem! That is something we often hear at CGR Products. An international restaurant & commercial kitchen equipment manufacturer contacted CGR Products with a potentially, large warranty issue. They needed help immediately. Their current gaskets were failing and allowing steam to intrude into the oven’s electronics during a steam cleaning cycle. (Fuji film…

Saving an Enclosure Manufacturer Money without Being Asked

“It’s nice when a supplier offers a cost-reducing solution without even having to ask” – OEM Manufacturer A current customer of CGR Products, an electrical enclosure OEM (Original Equipment Manufacturer) was developing a new line of large metal enclosures. The engineers at the manufacturer designed the gasket for the doors as a 1 piece design….

Reducing Costs with Kaizen Events

Unconventional Tooling Design Layout Results in Higher Yield, Lower Material Cost The Challenge: High-volume production requires controlled manufacturing processes in order to ensure that long-running jobs get out the door on time, meet specifications, and are cost-effective. In a recent project with a large automotive customer, CGR sought to reduce costs while ensuring that production…

Reducing OEM Assembly Line Backlogs with Smart Packaging

When a commercial small engine builder came to CGR with a costly gasket part and backlogged assembly line, we sought to find a solution that would improve production efficiency for the OEM. The commercial small engine builder was receiving die-cut rubber coated metal-clad parts in bulk boxes from their supplier. The bulk delivery resulted in reduced…

Quick Solution for a Discontinued Raw Material

CGR Products has a history of providing gasket and seal solutions to our customer’s most difficult problems. This was exactly the case with a large truck manufacturer that we helped engineer a new material to seal a gap after the supplier discontinued the original raw material. Beginnings A few years ago, CGR was approached by…

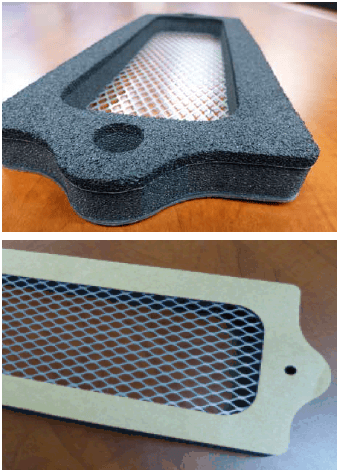

Protecting Loader Engines with a Custom-Fit Screen and Gasket

For any company, loaders are a major investment, and it’s best practice to protect the loaders from unnecessary wear and damages. The problem with some loader models is that performing routine maintenance leaves the loader engine exposed. Dirt, rocks, and even tools could fall into the air intake and cause damage to the engine. The Problem…