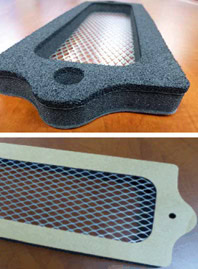

CGR Products die cuts and fabricates materials into precision components for the industrial OEM markets.

Our combined 190,000-square-foot facilities are equipped with over 100 different pieces of equipment that handle low, medium, or high volume production runs efficiently and accurately. We offer a number of manufacturing technologies including die cutting, kiss cutting, laminating, milling, slitting, turning, knife cutting and waterjet cutting. Our dedicated team can drastically reduce lead time using our in-house tool and die capabilities.

Cutting Capabilities

Includes die cutting, kiss cutting, waterjet cutting, knife cutting, and more.

Custom Fabrication

Includes lamination, beaded gaskets, assemblies, and distributed components.

All our facilities are ISO 9001:2015-certified and meet stringent TS 16949, GFA, ASTM, RMA, UL, and Mil-Spec requirements. Our rigorous quality control standards enable us to strive for continuous improvement in our product development methodology.

Why CGR?

Since 1963, our team at CGR Products has provided a wide range of custom fabricated flexible and non-metallic precision components for OEM customers. We serve a number of markets including automotive, marine, appliance, tooling, electrical, small engine assembly, and more.

CGR’s team produces a wide range of products for various industrial OEM markets. High tolerance parts such as lantern rings, rollers, food equipment, wear plates, seals bearings, washers, back-up rings, bushings, pumps, and conveyor parts are just a sample of what we can produce.

Our material lineup is extraordinary, with capabilities to field a wide range of materials for different product applications. This includes ABS, Delrin AF, rubbers, electrical insulation, graphite, fiberglass, Mylar, PEEK, Neoprene, Plexiglas, polycarbonate, PVC, urethane, PTFE, rubber, and other materials custom designed to work with your product design.

All of our products undergo intense scrutiny and quality control procedures using a full lineup of inspection tools from standard calipers to Virtek LQC scanners. We take quality seriously, offering certificate of conformance reports and SPC inspection documents for client reference.

Our team also provides a myriad of additional value-added services through our OEM Partner Program, which include vulcanizing, assembly, bar coding, packaging, reverse engineering, part stocking, stripping, and inventory management. For standard material production, our lead times are usually one week or less while additional time may be needed depending on the material chosen.

Our experience at CGR Products spans a wide variety of industries. We’ve worked with numerous OEM suppliers and manufacturers throughout the globe on a variety of applications. Whether you’re in the automotive, electrical, HVAC, medical equipment, power tools, lighting, electronics or any number of industries that require precision non-metallic parts, our team can navigate your design to success.

Please refer to the table below for our capability specifications.