Water jet cutting technology continues to be a leading process due to its versatility and quick turnaround capability for gaskets and seals.

Manufacturers are realizing that there are virtually no limits to water jet cutting and machining. Shops of all sizes are realizing greater efficiency and productivity by implementing water jets in their operations.

Water jets are becoming the machine tool of choice for many fabricators. Since abrasive water jet technology was first invented in the early 1980s, the technology has rapidly evolved with continuous research and development.

What makes water jets so popular?

- Produces gaskets with no heat distortion, or mechanical stresses caused by other cutting methods

- Can cut with a narrow kerf, and can provide better usage of raw material since parts can be tightly nested.

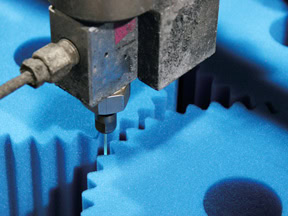

- Can cut virtually any material, up to 9″ thick without edge concavity typically seen in flat bed cutting.

- Significant cost savings per part in industries that have traditionally defined productivity by cost per hour.

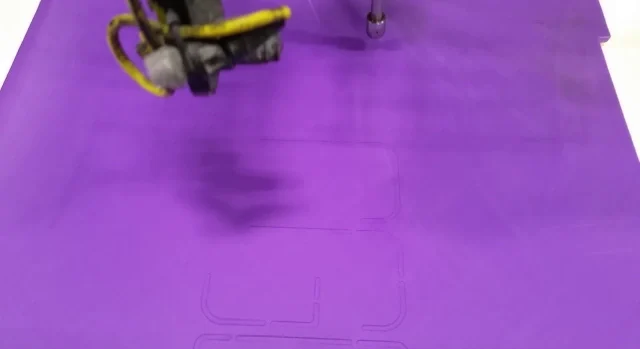

CGR can fabricate products of most all shapes and sizes utilizing a water jet cutting process. water jet cutting is an ideal choice for samples, prototypes, and quick-turn jobs.

CGR Products uses a high pressure stream of water to cut, with our water jet cutting offering excellent material yield and the ability to cut materials that are more difficult to cut with a die. Utilizing a CAD operating system, CGR Products water jet equipment has a rapid changeover time and allows for easy dimensional changes to parts.

Capabilities and Ranges for Waterjet Cut Shapes

- Ideal for samples, prototypes, and quick-turn jobs

- Able to cut 76″ wide x 88″ length

- Four head design allows for multiple cuts

- Product fabricated from the thinnest gauge flexible, pliable shim materials (0.002″) up to 9″ foams

- No tooling or tool maintenance

- Cuts without heat, therefore no heat affected fatigue zones

- Normally held tolerances at +/- .030″

- Cuts virtually all materials

- Prototyping

- High material utilization

The CGR water jets are capable of cutting rolls up to 76″ wide and of unlimited roll length. Our water jet fabricator CAD system design allows for maximum yield gains compared to standard press die cutting and it’s four head design allows for multiple cuts for faster production time.

CGR water jet cutting services allow us to fabricate products from the thinnest gauge flexible, pliable shim materials (0.002″) up to 9″ foams.

The CGR water jet’s requires no tooling or tool maintenance, lowering your initial set up charge. Our non-abrasive waterjet cuts non-metallic items. Our abrasive waterjet cuts hard materials such as metals and thick plastics. All our waterjets are environmentally friendly, are CAD reading and design capable and allows for .dxf and .dwg files.

View the table below for more information, or feel free to contact CGR today.