As a Preferred Converter for Rogers Corporation, CGR Products is your go-to converter of die cut flexible materials for Electric Vehicle (EV) Batteries. CGR Products provides solutions for thermal runaway, sealing out elements, heat shielding, gap fillers, battery cushioning, and more. CGR Products is a leading converter to solve challenges for EV battery manufacturers.

Die Cut Battery Pads & Cushions

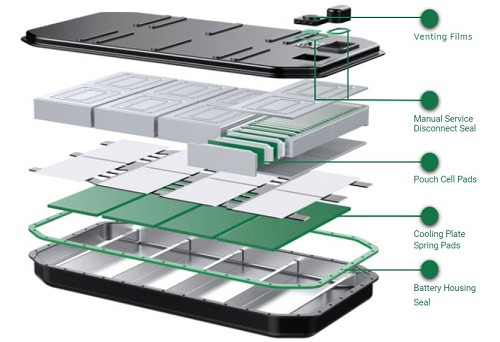

CGR Products die cuts battery pad cushions and compression pads using Rogers materials that must be firm enough to hold the battery cells in place, while also maintaining compression as the cell expands and contracts. Battery pads made from PORON polyurethane and BISCO silicone foams have a unique ability to produce a very consistent level of force across a range of compressions. PORON pads and BISCO silicone battery compression pads are die cut at CGR Products using a variety of sophisticated machinery to hold tight tolerances per the battery manufacturer specifications. Additionally, Rogers die cut foam pads isolate and dampen noise and vibrations in the battery.

Die Cut Battery Seals

Rogers Corporation Battery Materials Diagram

Sealing the battery enclosures from potential damage caused by the elements and road debris is critical to its operation. CGR Products die cuts a variety of PORON and BISCO materials to protect sensitive components from water, dust, and the elements. Gaskets fabricated from BISCO silicone material seal out water, dust, and debris while providing exceptional temperature and UV resistance. PORON polyurethane material is designed to reliably hold a consistent force, keeping battery cells aligned, sealed from dust and fluid, and isolated from the damaging effects of vibration.

Die Cut Venting Films

EV Batteries need protection from harsh external conditions. Usually located on the underside of the vehicle, EV battery enclosures protect the cells from exposure to water, dust, debris, and other elements. EV battery enclosures also undergo temperature and pressure changes that can lead to problems without proper venting that can lead to potentially dangerous thermal runaway conditions. Die cut seals are required for venting to reduce heat and protect against environmental elements

Rogers DeWAL® V-Series venting membranes are engineered to vent and protect a wide range of critical enclosure applications. These venting membranes can be die cut and leverage the unique properties of expanded polytetrafluoroethylene (ePTFE) to enhance heat and air ventilation while protecting sophisticated electronics sealed in automotive electrical, telecommunications, and lighting enclosures.

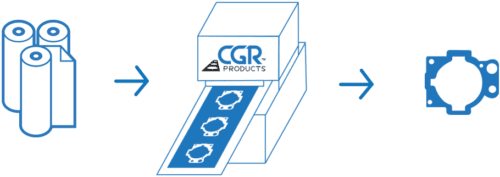

Working with CGR Products

Only a select few companies that partner with Rogers are recognized as a Rogers Preferred Converter. A Preferred Converter is the highest designation Rogers gives a company that demonstrates expertise in converting capabilities and holds to the highest standards.

At CGR Products, we have maintained Rogers Preferred Status since the inception of the program. We continuously thrive to stay on the cutting edge of technology and converting processes. Our capabilities allow us to convert Rogers products to your exact specifications at prices that will keep you competitive in your market space.

To learn more about Rogers Corporation’s portfolio of EV Battery material options, visit the Battery Applications Page.