Precision Die Cut Gaskets, Seals, and Components for the Generator Market

CGR Products is an experienced, custom component fabricator specializing in high-performance parts for Original Equipment Manufacturers (OEMs) in the Power Generation industry. From emergency backup generators and portable units to large industrial diesel systems, our die cut and fabricated solutions are engineered for extreme environments—withstanding high heat, continuous vibration, and aggressive fuels and coolants. We partner with you from prototyping to high-volume production to deliver durable, reliable components.

Component Solutions

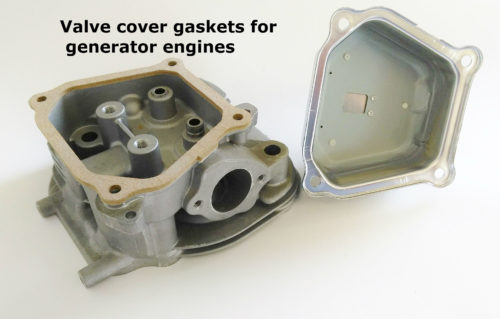

Our custom gaskets and seals are vital for preventing leaks in critical areas. We cut and fabricate materials like Graphite, Silicone Rubber, Cork, Viton, Nitrile (Buna-N), and EPDM to meet demanding fluid compatibility and temperature requirements.

-

Generator Valve Cover Gasket: Precision cut seals designed to maintain integrity under engine heat and pressure.

-

Graphite Die Cut Gaskets: Used for exhaust and other high-temperature applications.

-

Oil Pan, Fluid Housing, and Flange Seals: Customized to resist specific fuels, oils, and coolants.

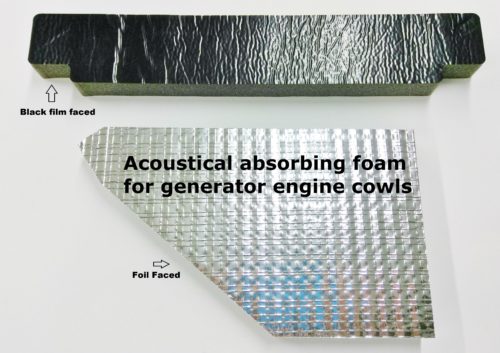

Acoustical and Thermal Management

Generators often require material solutions for noise reduction and heat protection. We supply specialized open and closed cell foam for sound dampening and thermal barriers to protect sensitive electronics.

-

Die Cut Generator Acoustical Foam: Custom-shaped foam for lining enclosures to significantly reduce decibel output.

-

Thermal Shielding: Components designed to redirect or dissipate heat away from critical engine parts and housings.

-

Vibration Dampeners: Elastomeric materials used under mounting points to minimize component wear and operational noise.

Fluid and System Components

We convert materials into highly accurate components for various sealing generator applications, ensuring system reliability.

-

Insulators and Dielectrics: UL listed materials for safely managing power connections and ingress protection.

-

Filters and Screens: Custom-cut media for air and fluid filtration systems.

Capabilities & Authority

World-Class Fabrication and Material Expertise for Generator OEMs

Leveraging over 100 top-quality machines across multiple facilities, we offer a complete range of services tailored to your generator component needs:

Waterjet Cutting: Ideal for rapid prototyping and components requiring extremely tight tolerances.

Rotary Die Cutting: Perfect for high-volume, cost-effective production runs.

Lamination: Custom bonding of materials (e.g., adhesive application) for easier installation.

Value-Added Services: Kitting, assembly, and packaging solutions for streamlined manufacturing

Learn more about our precision die cutting and other fabrication methods.

Die Cut Gaskets and SealsQuality and Material Certifications

As an ISO 9001:2015 and IATF16949 certified company, quality is at the core of our operations. We utilize premium materials from trusted partners, and we are a 3M Preferred Converter and Rogers Preferred Converter. Premium materials that guarantee peak performance in every generator component.

Ready to Design and Source Your Generator Components?

Our expert team is ready to assist with material selection, prototyping, and high-volume production. We understand the stringent quality requirements of the power generation industry.