High-Performance Die Cut Gaskets & Seals for the Oil & Gas Industry

The oil and gas industry operates in some of the most challenging environments on Earth, demanding components that can withstand extreme pressures, corrosive chemicals, fluctuating temperatures, and constant vibration. At CGR Products, we specialize in fabricating precision die cut gaskets and seals specifically engineered for these harsh conditions. From upstream exploration and drilling to midstream transportation and downstream refining, our high-performance sealing solutions are crucial for ensuring operational integrity, safety, and preventing costly leaks in critical equipment. We work with leading OEMs and suppliers to deliver reliable, durable components that meet stringent industry standards.

Reliable Sealing Solutions Across Oil & Gas Operations

Upstream: Exploration & Production

In drilling, extraction, and wellhead operations, components face intense pressure and exposure to raw crude, natural gas, and drilling fluids.

- Wellhead Equipment: High-pressure flange gaskets, casing seals.

- Drilling Rigs & Equipment: Mud pump gaskets, manifold seals, vibration dampeners.

- Subsea Equipment: Specialized seals for ROVs, control systems, and connectors requiring long-term reliability in corrosive saltwater environments.

Midstream: Processing & Transportation

The safe and efficient transport of oil and gas through pipelines, pumps, and compressors requires robust sealing to prevent leaks and maintain system integrity.

- Pipeline Flanges: Gaskets for secure pipe connections, preventing leaks during transport.

- Compressors & Turbines: Seals for rotating equipment, critical for maintaining operational efficiency and safety.

- Storage Tanks: Tank lid seals, inspection port gaskets, and overflow seals.

Downstream: Refining & Petrochemical

Refineries process crude oil into various petroleum products. Components here must withstand a wide array of aggressive chemicals and extreme temperatures.

- Heat Exchangers: Gaskets to prevent cross-contamination and ensure heat transfer efficiency.

- Valves & Pumps: Seals that resist acids, solvents, and high-temperature steam.

- Pressure Vessels: Manway gaskets and inspection port seals.

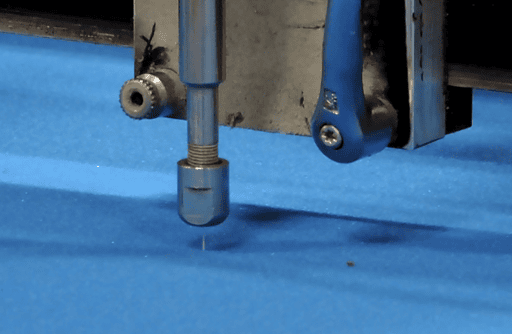

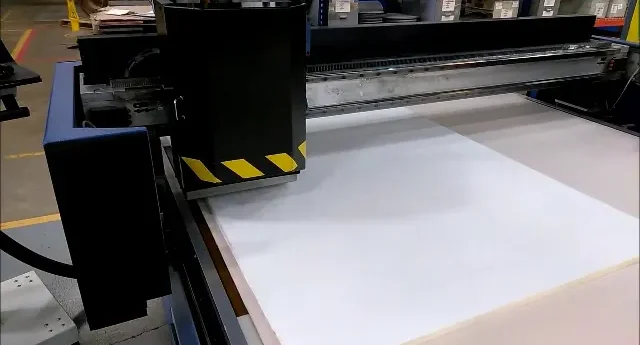

Engineered Materials & Precision Fabrication for Demanding Environments

Materials for Extreme Conditions

Selecting the right material is paramount for oil and gas applications. CGR Products offers a broad range of high-performance elastomers, non-metallic materials, and composites known for their chemical resistance, temperature stability, and durability.

- Viton® (FKM): Excellent resistance to aggressive fuels, oils, and chemicals, with high-temperature capabilities.

- Nitrile (Buna-N): Superior resistance to petroleum-based oils and fuels.

- Graphite: Ideal for extreme high-temperature and fire-safe applications.

- Compressed Non-Asbestos Fiber (CNAF): Economical sealing for a wide range of chemicals and temperatures.

- PTFE (Teflon®): Exceptional chemical inertness for highly corrosive media.

Download our Chemical Compatibility Guide to ensure optimal material selection for your application.