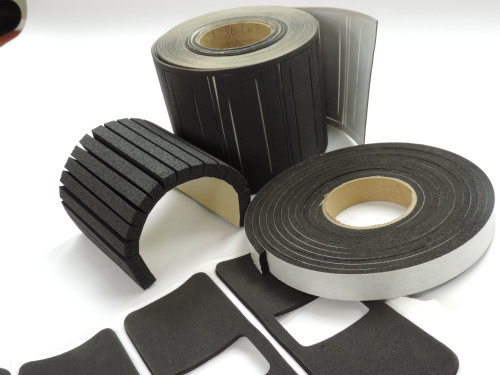

Foam materials are lightweight, versatile, and durable, which makes them an ideal option for gaskets and seals across many of the industries that we serve.

CGR Products can fabricate and die cut a variety of foam and sponge rubber materials. Foam is incredibly efficient to work with as CGR can hold tolerances as low as .015” on materials with a firmer durometer.

We offer both open and closed cell foam materials, and our customers have used foam rubber gaskets and sealants across a number of industries including appliances, automotive, electronics, HVAC, lighting, marine, power equipment, and many more.

The range of foam rubber materials we offer includes:

- Neoprene

- EPDM, SBR and Neoprene blends

- Polyurethane

- PVC/NBR

- Silicone

- Volara (XLPE)

- Microcell Urethane Foam (PORON)

- And more

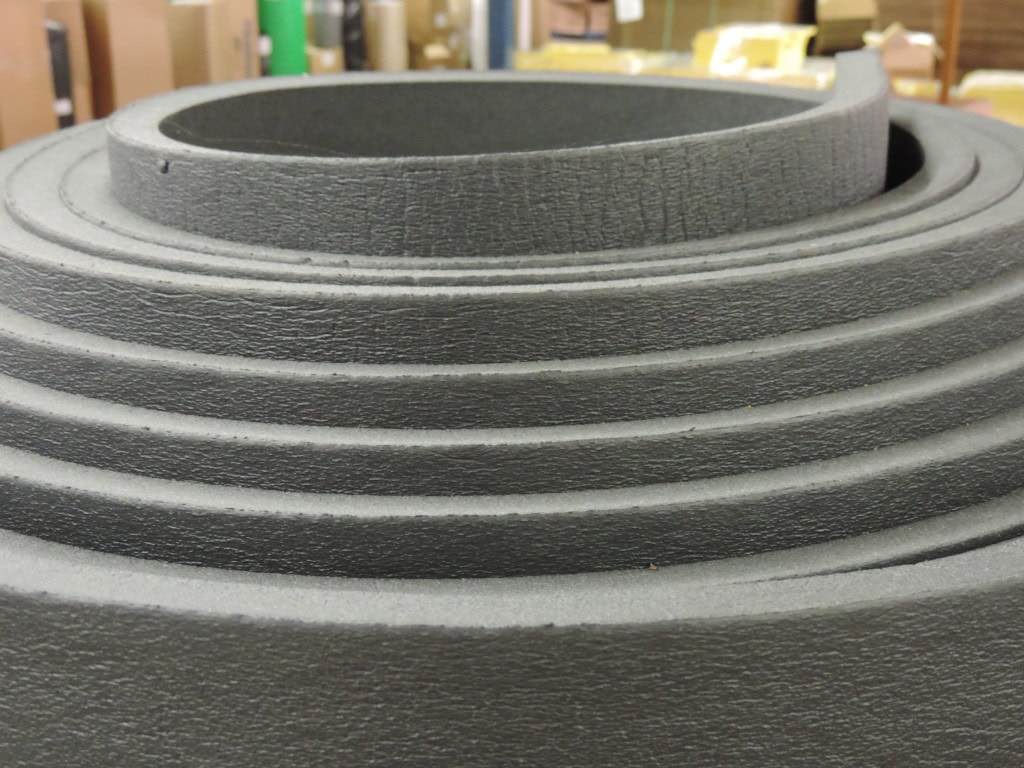

Foam rubber can fill large voids and gaps, and also has cushioning properties to help lessen impact between two substrates. Closed cell foam is perfect for sealing and helps reduce liquid and gas flow whereas open cell foam offers more flexibility and can be manufactured in either high or low density.

Foam can also be treated to have resistance properties depending on the intended application. It can be laminated and applied with adhesives that withstand intense pressure situations. Foams are naturally resistant to fire and burning and can be sealed to withstand many chemicals and acids. Additionally, foam is ideal for outdoor applications because it resists weathering, UV rays, and fungi.

Please view the table below for a complete list of open- and closed-cell foam materials.

| Open & Closed Cell Foam | Description | Suppliers |

|---|---|---|

| Closed Cell Foams: * EPDM * Neoprene * Buna-N (Nitrile) * Neoprene/SBR/EPDM Blend * PVC/NBR Blend * Silicone * Fluoroelastomer (Viton) * PVC Foam | * Pure EPDM. Excellent resistance to ozone, UV, weather, and elevated temperatures. * Very popular and used for moderate exposure to oils, ozone, and weathering resistance. * Good for resistance to oils and petroleum products. * Widely used. Good for general purpose applications. An industry standard. * Continuous roll products with PVC added to increase resistance to ozone and abrasion. * Excellent heat resistant foam. Resistant to sunlight, moisture, a * Outstanding resistance to heat, chemicals, solvents, oils, and fluids. * Vinyl foam products are used for long life seals against moisture, air, light, and dust applications. | * Armacell, K-Flex * Armacell, Monmouth, K-Flex * Monmouth, * Armacell, Monmouth, K-Flex* Armacell * Rogers BISCO, Diversified Silicone, Saint Gobain * Gaska Tape, Novagard |

| Cross Linked Polyethylene Foam (XLPE)(Volara) | Flexible closed cell material. Has low water absorption and excellent thermal insulation. | Sekisui Voltek, Palziv, Armacell, Worldwide Foam |

| EVA | Good for moisture and high tear resistance. Used in many padding and flotation applications. | Vulcan |

| Microcell Urethane Foam (PORON) | High performance urethane foam is used for quick recovery from compression. | Rogers PORON, Saint Gobain |

| Open Cell Foams: * Neoprene * Natural Rubber | * Absorbent, comes with textured skin, used for vibration and sound dampening. * Absorbent, comes with textured skin, used for vibration and sound dampening. | * Griswold * Griswold |

| Semi-Open Cell Soft (Crushed) Foam | Used for super soft applications where high compressibility is required. | Armacell |

| Urethane Foam: * Standard Polyurethane * Reticulated Filter Foam | * Low cost open cell foam used for sealing dust, dampening, and vibration control. * Available from 10 ppi to 80 ppi. Used in filtration applications in either Polyester or Polyether. | * Woodbridge, Crest, Future Foam * Woodbridge, Crest, Future Foam |

We stock a wide variety of foams to help reduce lead times. Additionally, repeat products contain stored setup information for turnaround times often as low as 24 hours.

CGR can provide quotes or provide more information if needed on specific item details. Please contact us today to talk more in-depth about the exciting solutions that foam rubber fulfills.