Our UL approved DK1111LD sponge material with rubber adhesive supports UL properties and will do the same for your application.

This UL listed combination utilizes a Neoprene/EPDM blended sponge with a high tack rubber adhesive.

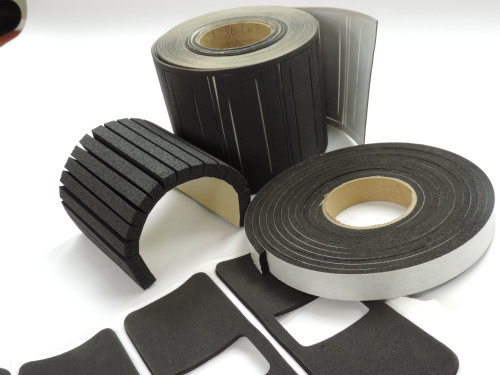

It is available in sheets, rolls and custom shapes and sizes for your convenience.

Common applications include enclosures, control panels, and electrical components and the appliance market.

The rubber adhesive provides an excellent “quick stick” to most substrates.

About the Adhesive

- General Purpose, high tack, rubber-based adhesive.

- Extremely high bond strength to most surfaces.

- Excellent versatility for lamination to foam material.

- Excellent dimensional stability with polyester carrier.

- Densified Kraft liner for rotary die cutting.

Learn more in our 3M Acrylic Adhesives Data Library >