CGR Products is your go-to converter of die cut flexible materials for Electric Vehicle (EV) Batteries. CGR Products provides solutions for thermal runaway, sealing out elements, heat shielding, gap fillers, battery cushioning, and more. As Preferred Converters for many of our suppliers, CGR Products is a leading converter to solve challenges for EV battery manufacturers.

Thermal Management

Thermal management of EV batteries and their systems are a top concern of electric vehicle manufacturers. Battery packs must operate at a proper temperature and at optimal pressure via the use of battery compression pads. Electric vehicle battery makers incorporate the use of specialty materials between cells and modules – or around the pack – to help slow down or eliminate the propagation of thermal events.

CGR Products works with EV battery manufacturers to die cut and supply items such as:

- Battery Pack Heat Shields

- Cell Separators

- Electrical Insulation

- Thermal Gap Fillers

- Thermal Runaway Protection Pads

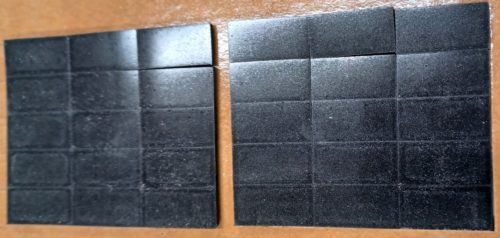

Battery Compression and Vibration Pads

Battery pad cushions, or compression pads, used inside an EV pouch cell battery pack must be firm enough to hold components in place and compressible enough to withstand dimensional changes to the pouch cells over the life of the battery. CGR Products die cuts materials with unique abilities to produce a very consistent level of force across a range of compressions.

Batteries also need to be protected from impact and vibration. Vibration must be managed both within the pack and between the pack and the vehicle. CGR Products provides solutions for vibration dampeners and impact isolators via die cutting urethane and silicone foams.

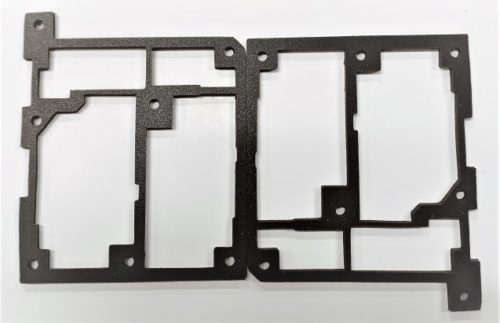

Battery Ingress Protection

Gaskets and Seals are needed to protect battery enclosures from potential damage caused by the elements and road debris. CGR Products die cuts a variety of materials for enclosure gaskets that protect batteries from the elements while allowing items to be serviced over the life of the battery.

Silicone and Urethane foams are commonly used to seal out dirt and fluids while also helping to isolate vibrations. Like other enclosures, EV battery enclosures also undergo temperature and pressure changes that make it important for ingress protection gaskets to perform flawlessly for the battery’s lifetime.

Venting Membranes

EV batteries present unique venting challenges including potentially dangerous thermal runaway conditions. If lithium-ion battery cells are damaged, this can trigger other cells to decompose, leading to a thermal runaway condition and a potentially harmful scenario. Die cut venting membranes are used for these applications. An ePTFE venting membrane allows for enhanced heat and air ventilation, while burst vents enable quick evaluation of heat and pressure. These are critical to all thermal runaway protection systems.

CGR Products and EV Batteries

CGR Products will work with you during the early stages of your project to high level production volumes. We have a vast network of preferred suppliers and manufacturers with expert advice in making the right material selection. We have 4 locations in the USA with over 190,000 sq ft of manufacturing space and are premier converters of foams, films, rubber, insulation, lamination, and more.

Feel free to contact us today about your upcoming EV Battery die cut applications.