Large, one-piece electrical enclosure door gaskets can look simple on paper, but when the “part” is essentially a giant square, the entire interior becomes scrap. That’s exactly what an electrical enclosure OEM faced while launching a new line of large metal enclosures.

Their initial concept specified a one-piece, thick gasket in a low-cost open-cell urethane. In testing, the material didn’t rebound well and couldn’t hold sealing force over time. Meanwhile, the one-piece geometry drove material waste and cost far more than expected.

With drawings already in circulation, the team needed a cost-reducing fix that maintained sealing performance without reworking the door design.

Customer Problem

The OEM’s one-piece gasket design produced excessive scrap and cost, and the open-cell urethane under consideration failed to recover after compression, jeopardizing long-term sealing performance.

The challenge was to reduce material waste, upgrade the material, and maintain the electrical enclosure existing door layout while ensuring efficient assembly.

Design Requirements

To be successful, the solution needed to:

- Reduce scrap and increase sheet yield

- Deliver repeatable compression and rebound over time

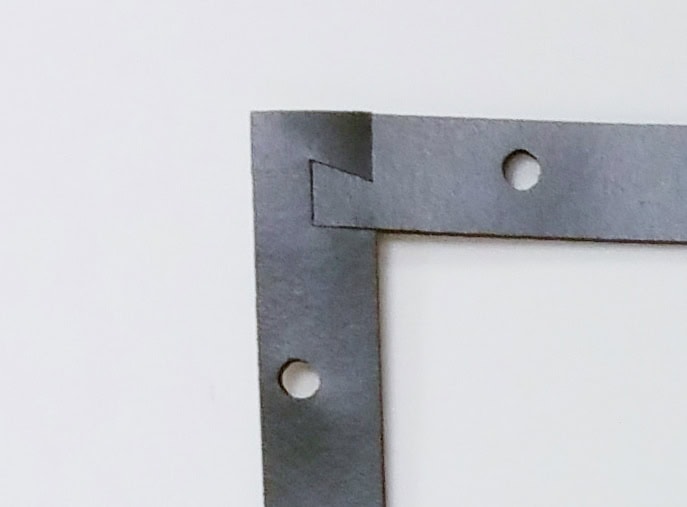

- Fit existing door geometry and hole pattern

- Provide low compression set and stable performance in service

- Support straightforward, error-free assembly at scale

The Solution

CGR Products, a Preferred Converter of Rogers Corporation, and Rogers Corporation partnered together to re-engineer both material and manufacturability.

- Material upgrade: A switch was made to PORON® 4701-40 microcellular polyurethane (Soft), chosen for its excellent rebound and low compression set—and ideal for enclosure door seals that must maintain force over time.

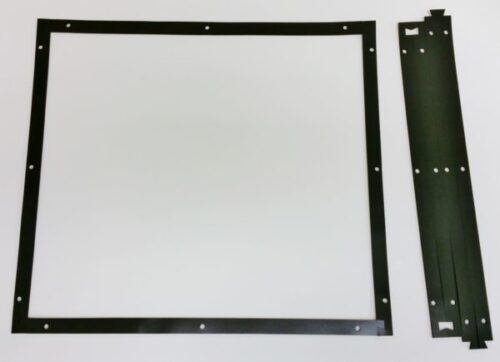

- Design for yield: CGR reconfigured the one-piece frame into a four-side, interlocking dove-tailed design. Instead of cutting out a huge “window” of scrap, the gasket is built from efficiently nested side strips that join at the corners—eliminating the interior waste.

The OEM requested quotes for both the original one-piece and the dove-tailed alternatives; prototyped dove-tail sets matched the door layout and passed testing, so engineering updated the drawing and purchasing moved to production.

The Material: PORON® Polyurethane

PORON® 4701-40 (Soft) material was specified to meet the enclosure’s sealing demands:

- Excellent compression set resistance → maintains sealing force long-term

- Reliable rebound and recovery after repeated closures

- Tight thickness tolerances for consistent fit around the perimeter

- Conformability to minor surface variation in metal doors and flanges

The Process

CGR’s product development and converting teams worked shoulder-to-shoulder with the OEM:

- Reviewed the large one-piece geometry and sheet utilization

- Proposed dove-tailed corners to convert the frame into four efficient sides

- Cut and delivered prototypes for fit and compression testing

- Finalized production nesting to maximize yield and minimize scrap

- Supplied ready-to-assemble sets for clean, repeatable installation

The Result & Key Takeaway

- Yield: from ~1 set per 1-sq-yd sheet to ~9 sets per sheet

- Cost: approximately 80% savings versus the original one-piece design

- Performance: upgraded to PORON® 4701-40 polyurethane for long-term seal integrity

- Waste: interior “window” scrap eliminated via dove-tailed side strips

For electrical enclosure engineers, this case shows how material selection plus design for manufacturability can deliver a better seal at a fraction of the cost without changing the door.

Partnering with CGR

Our staff are experts at finding creative solutions to manufacturing problems. At CGR Products, custom solutions are truly our specialty.

Do you have a problem that requires an innovative solution? Contact us today to discuss how we can help.