While CGR Products specializes in die-cutting a wide range of gaskets and seals on a daily basis, when a document archive company approached us online with an unusual request to cut mylar sleeves for historical documents, we eagerly took on the challenge.

The Challenge: A Time-Consuming Manual Process

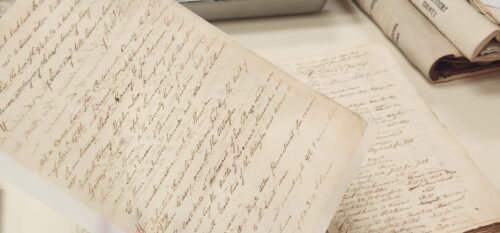

A leading archival preservation company, dedicated to safeguarding historical documents for museums, universities, and government institutions, faced a growing challenge: their manual process of cutting mylar sleeves was slowing production and straining labor resources. Archivists and technicians spent a large portion of their day cutting mylar sleeves, taking valuable time away from document assessment and restoration.

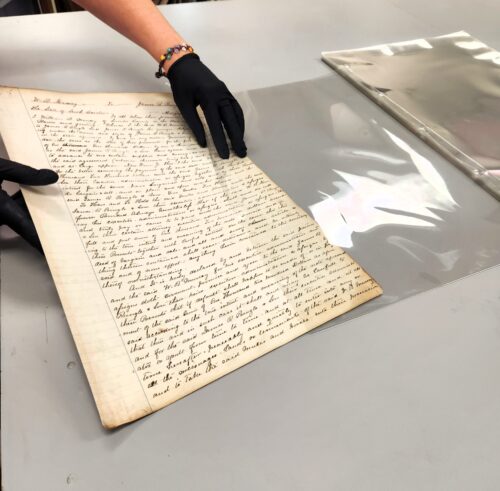

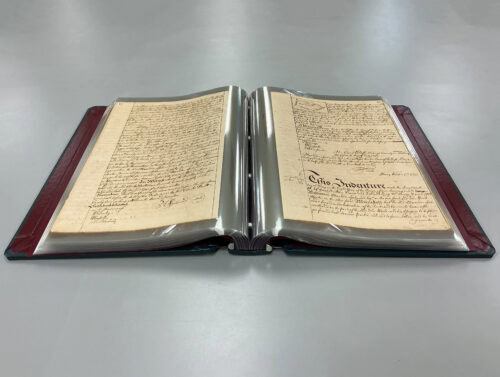

The process of protecting fragile, aging documents involved manually cutting and preparing individual sleeves of archival-grade mylar film. This material is chosen for its chemical inertness, optical clarity, and resistance to environmental damage.

Each sleeve—used to protect fragile manuscripts, maps, and letters—required meticulous hand-cutting to meet exact archival standards. As demand surged, the company needed a scalable solution that wouldn’t compromise quality

The Solution: Partnering with CGR Products

The Solution: Partnering with CGR Products

The preservation company approached CGR Products with a unique request: to transform their labor-intensive, manual process into a streamlined, high-volume operation.

CGR Products’ team collaborated closely with the archive’s conservation specialists to understand the precise requirements for the mylar sleeves. The project’s specifications were clear:

- Dimensions: A variety of sizes were needed for documents, from small letters to larger documents.

- Tolerance: Extreme precision was critical to ensure a perfect fit

- Cleanliness: The mylar sleeves needed to stay as clean as possible.

CGR Products Challenge

While the preservation company brought a clear need, CGR Products faced a unique challenge of its own. The Mylar sleeves arrived pre-sealed on three sides, making traditional die-cutting methods impractical. To ensure consistent cuts without damage and staying in tolerance, CGR’s engineering team developed a custom alignment tool that precisely positioned each sleeve for cutting. This innovation allowed CGR to maintain tight tolerances and deliver flawless results—proving once again that when precision meets ingenuity, even the most complex jobs become scalable.

The Results: A New Way in Document Preservation

The partnership with CGR Products delivered transformative results for preservation and reducing labor.

- Increased Efficiency: The archive’s staff no longer spent valuable hours on manual cutting. The pre-cut sleeves were delivered ready for immediate use, freeing up conservators to focus on the delicate work of document restoration.

- Quality & Consistency: Every mylar sleeve is die cut with precision, identical reproduction, ensuring a high level of uniformity.

- Cost Savings: The reduction in labor hours through die-cutting resulted in significant long-term cost savings for the institution.

- Accelerated Project Timelines: With a continuous, reliable supply of ready-to-use sleeves, the archive is able to make substantial progress protecting a greater volume of historical materials for future generations.

This case study demonstrates how a specialized manufacturing process, like CGR’s custom die-cutting, can be applied to a seemingly unrelated field, like historical preservation, to solve a critical operational challenge and fundamentally improve a valuable, mission-driven workflow.

HF Group has remained dedicated to excellence and service to their clients since 1821. Clients include many of our nation’s oldest and most prestigious research libraries, museums and archives.