Customer Problem

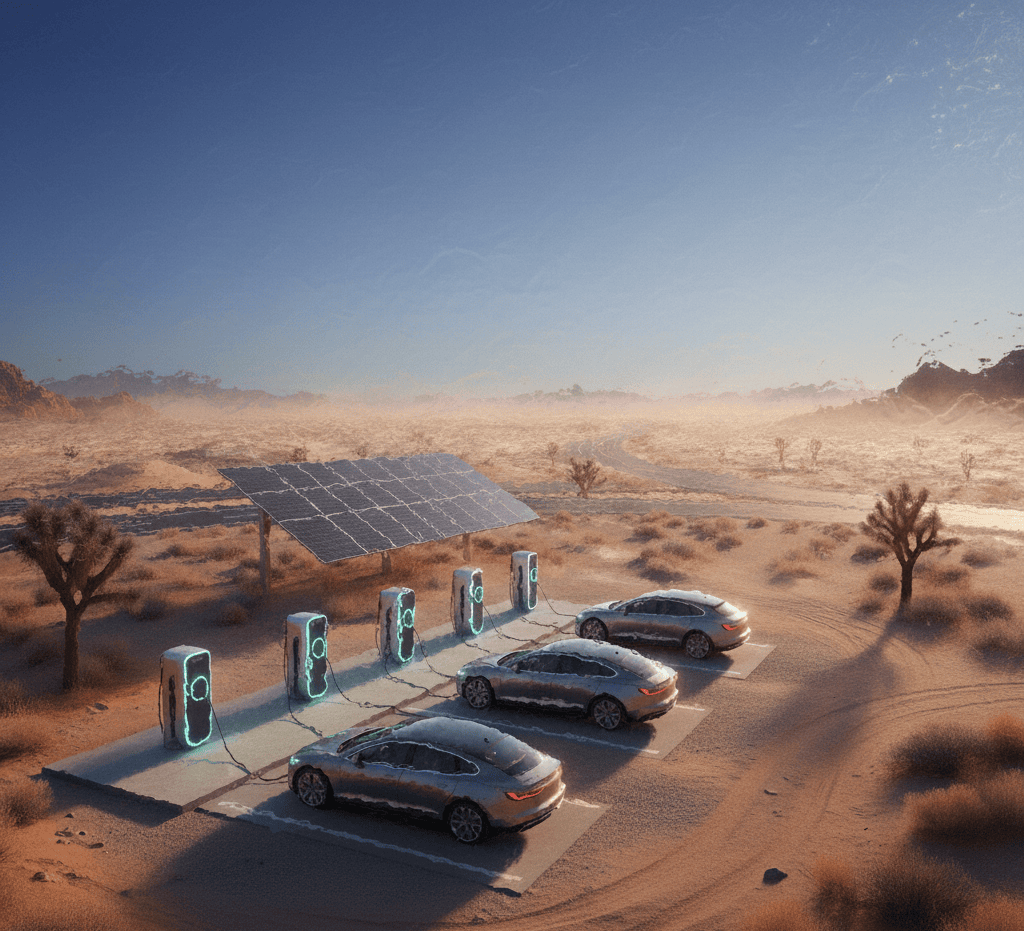

Pump and charging station seals may look simple on paper, but in real-world use they face a wide range of environmental stresses. Several vital components of these fixtures are the electronics. From digital display screens to credit card readers, these electronics must be protected from environmental exposures. The OEM’s original design relied on low-cost sponge materials, but testing revealed significant drawbacks:

- Compression set: sponge seals quickly lost their ability to rebound, compromising long-term sealing force.

- Temperature extremes: pumps located in hot climates like Arizona or cold regions like Alaska saw premature seal degradation.

With pumps and EV charging stations installed across diverse climates, the OEM needed an material strategy that could maintain performance without driving up unnecessary cost and have ingress protection as the primary goal for delicate electronic.

Design Requirements

The solution needed to:

- Maintain reliable compression and rebound over time

- Resist both hot and cold temperature extremes

- Provide moisture protection where environmental exposure was a concern

- Balance cost and performance depending on application and climate

- Fit existing geometries without requiring design changes

The Solution

CGR Products, a Rogers Preferred Converter, partnered with Rogers Corporation to upgrade the OEM’s sealing approach. Together, the teams evaluated the performance requirements across different pump environments and matched them with the right Rogers materials.

The Material: BISCO® Silicone Foams

- Excellent rebound and low compression set, maintains sealing force long-term

- Reliable stability across a wide temperature range, from extreme cold to extreme heat

- Outstanding weather and moisture resistance for outdoor applications

- Example: BISCO HT-800 is a trusted choice for gas pump seals and EV charging stations exposed to harsh climates

The Material: PORON® Polyurethane Foams

- Excellent compression set resistance for reliable long-term sealing in milder conditions

- Cost-effective solution when extreme moisture or temperature resistance is not required

- Conformability to design geometry with consistent thickness tolerance

- Ideal for EV charging stations or pumps in moderate climates

- Example: PORON 4701-40 provides consistent rebound and reliable sealing in moderate environments

Application Fit

- Gas station pumps: Outdoor seals facing sun, snow, and rain transitioned to BISCO HT-800 for durability and weather resistance.

- EV charging stations: In moderate climates, PORON materials provided a cost-effective solution with reliable sealing. In harsher climates, BISCO silicone foams ensured protection against moisture and temperature extremes.

- Gaskets: Both materials were easily fabricated into die cut gaskets and seals. Both materials can be supplied with or without adhesive. This is useful depending on where it is used in the application.

The Process

CGR’s application engineers worked closely with the OEM to:

- Map out regional requirements for pumps and charging stations across different climates

- Prototype seals using both PORON and BISCO foams for testing

- Validate compression set, rebound, and moisture resistance in environmental conditions

- Deliver finished seals cut and assembled to OEM specifications for clean, repeatable installation

The Result & Key Takeaways

By pairing Rogers’ high-performance foams with CGR’s converting expertise, the OEM achieved

- Reliability: Seals now maintain long-term compression and rebound, preventing premature failures.

- Flexibility: OEMs can choose PORON for cost-efficient performance in mild climates, or BISCO silicone foams for extreme conditions

- Confidence: Whether in Arizona heat, Alaskan cold, or rainy coastal regions, pumps and charging stations remain sealed and protected.

For engineers, this case demonstrates how material selection plus converting expertise can deliver durable, cost-optimized sealing solutions without changing the underlying design.

Partnering with CGR Products

At CGR Products, custom solutions are our specialty. Our team is skilled in evaluating real-world application challenges and pairing them with manufacturable, cost-effective designs.

Do you have a sealing challenge in pumps, charging stations, or other demanding applications? Contact CGR today to discuss how we can help.