We have a problem! That is something we often hear at CGR Products.

An international restaurant & commercial kitchen equipment manufacturer contacted CGR Products with a potentially, large warranty issue. They needed help immediately. Their current gaskets were failing and allowing steam to intrude into the oven’s electronics during a steam cleaning cycle.

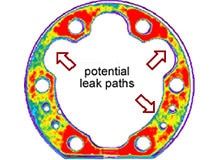

(Fuji film analysis showing

potential leaks paths of a

flange gasket)

CGR Products immediately went into action working hand in hand with the OEM manufacturer. We first reviewed all the designs and materials that were currently being used in the problem units. The next step was determining what the current sealing designs were and how it was effecting the units in question. To begin, we supplied Fuji films cut to the current gasket designs to their Engineering team.

Upon analysis of the Fuji films, it was evident that the sealing pressures were a problem for almost all the current designs. We also reviewed the current materials used to determine compatibility with the needed fit, form, and function of the gaskets end use.

Solutions

(Acceptable fuji film analysis

showing the redesigned

gasket and seal around the

perimeter)

CGR Products suggested several redesigns for all the gaskets and some different materials to help achieve the necessary sealing pressures and compressions to make an acceptable seal. The OEM engineering team was impressed by the findings and wanted to proceed to the next step of sampling.

CGR Products supplied revisions provided by the Fuji films analysis and cut sample gaskets to prove out the new designs and materials. The test results were just what the customer wanted to see. After in-house and field testing the customer implemented all the CGR suggested designs and materials. This quick action by CGR and the OEM’s Engineering team helped to avert an expensive and large-scale recall.

Victory

The final step was CGR Products expediting the cutting of the new designs and materials. CGR Products worked feverishly to meet very tight deadlines. In the end, the customer was able to supply kits to their field technicians and customers in a matter of weeks.

Are you ready to work with CGR Products?

CGR is able to work with engineers on many types of designs. We can advise of problems and obstacles that can arise, right from the beginning of the project. Contact us today to learn how we can improve your next project.