At Amorim Cork Composites — the world’s largest producer of cork and related materials — we’re committed to sustainability in everything we do: We recycle, reuse, and reinvent entirely natural and organic materials. Understanding the versatility and value of cork in numerous applications, we’re proud to supply companies worldwide with top-quality, reliable cork products.

The Versatility of Cork

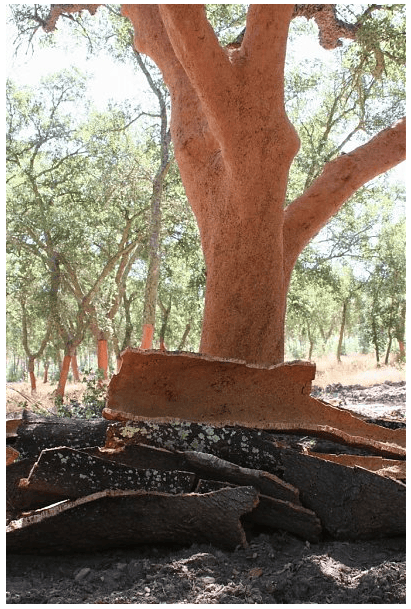

Cork grows from the bark of the cork oak tree, which thrives in the hot, dry climates of Portugal, Spain, and North Africa. Cork oak trees are not harvested until they’ve reached 25 years of age. After the first harvest, the bark is removed about every nine years. These trees can live for over 200 years.

After the bark is harvested in sheets about 3 feet wide, 6 feet long, and 3 inches thick, it is cleaned to remove any impurities. Soon after, the cork is cut into strips and, most often, cored to create wine stoppers; this is the primary use of cork. In fact, over 15 billion stoppers are sold each year to the wine industry. The cork not used in the stopper industry is processed and used in various other applications, including construction, sealing, composites, home and office, and flooring.

In its natural state, cork is composed of many cells filled with air pockets, making it ideal for sealing applications. Cork compresses within itself with no side flow, creating a reliable seal impervious to most fluids. Classified as a post-industrial recycled material, cork has been used since the late 1800s for industrial sealing applications.

Cork Solutions at Amorim

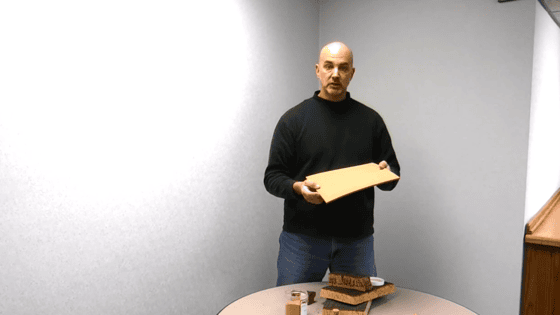

At Amorim, we’re especially proud of our P46 cork material. Our most popular product, P46 features high density and low compressibility. It’s typically used in friction applications in which heat is generated by pressure, as well as clutch applications.

P46 is readily available in custom-cut sizes up to half an inch thick, with one or both sides sanded. To discuss how Amorim’s materials can help with your next project, contact us today.

How CGR Can Help

CGR Products has a long history of custom cutting and fabricating for a wide range of materials including cork and rubber. Our services include custom die cutting, waterjet cutting, kiss and knife cutting, and more. Visit our Resource Library for access to our many free guides, eBooks, and whitepapers, or check out our Case Studies to learn more about our full scale of materials and capabilities.