CGR Products has been supplying various types of 3M™ Thinsulate™ materials to the automotive market for more than 10 years. The 3M™ Thinsulate™ NVH material (noise, vibration, and harshness) is used in a variety of applications across many different industries and provides a wide variety of sound absorption and dampening properties. The Advantages of 3M™ Thinsulate™…

CGR Products News Release

CGR Products News Release: Growth Leads to a 30,000 sq ft Expansion and New High Volume Manufacturing Machinery Click Here to read the full news release.

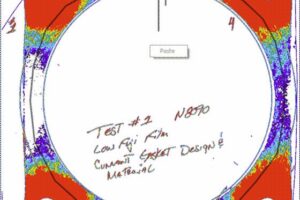

To Fuji or not to Fuji Test your Gaskets, That is the Question

Many variables can affect gasket sealing such as internal pressure, temperature, gasket design, and flange load. Sometimes it is necessary to dig a little deeper into the actual sealing picture when a difficult or critical sealing situation is encountered. In this article, we will explore a process we call “Fuji Testing”. How Fuji Testing Works…

Material of the Month: Felt

CGR Products stocks a large variety of materials for a wide range of applications. Flexible rubber sheeting, adhesive solutions, and fiber materials are just a few of our specialty options. Our Material of the Month series spotlights some of our favorite materials and their unique applications. This month, we’re discussing Felt. What is Felt? Felt…

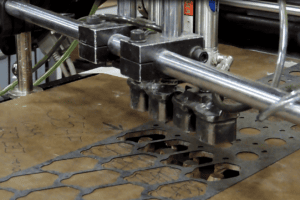

Rotary Die Cutting vs. Flatbed Die Cutting: Which Should You Use?

Die cutting is frequently used to fabricate unique shapes from rubber, plastic and foam materials. Before starting a die cutting project it is important to discuss all specific project requirements, including whether rotary die or flatbed die cutting is the best fit for the job. Each cutting method has its own distinct benefits based on…