Vendor Managed Inventory (VMI) can be an effective strategy for companies looking for cost savings and a more stable supply chain. In this post, we will outline the benefits of VMI as well as the services that CGR Products provides with these programs. What is VMI? VMI is a program where the supplier manages your…

New Year, New Videos! See What We’ve Been Doing at CGR

Water jet cutting, kiss cutting, custom die work — it was all on display at our Wisconsin Open House this past October. Our team was on-hand to help guests get acquainted with some of these state of the art machines, and took the opportunity to chat about some of our most successful recent projects. See…

![[INFOGRAPHIC] Insider’s Tips To Packaging Issues [INFOGRAPHIC] Insider’s Tips To Packaging Issues](https://www.cgrproducts.com/wp-content/uploads/chrtopblog-300x200.png)

[INFOGRAPHIC] Insider’s Tips to Packaging Issues

An OEM’s guide to avoiding common packaging issues and eliminating unnecessary costs While generally overlooked during production, packaging solutions have a significant impact on your project’s overall costs. For OEMs requiring custom fabricated rubber, foam, and plastic products — such as gaskets, seals and tapes — there are a number of packaging solutions to not…

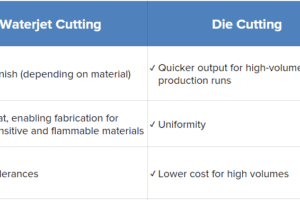

Die Cutting vs. Waterjet Cutting: Which One Should You Use for Your Project?

More cutting methods are available today than ever before. While friction sawing used to be the primary industrial material cutting option, there are now nearly a dozen viable choices. Not all cutting methods are created equal — which isn’t to say that one is categorically better than another, but rather that they all have their…

Meet the New Knife Cutting Machine at CGR: Flashcut Flex HD

Knife cutting is one of the fastest and most precise methods for producing parts. From prototypes to final products, no matter the shape or size of a design, knife cutting technology offers flawless production for a wide range of materials. We’re excited to feature brand new technology to the CGR Fleet from ATOM. “Cutting”-edge tooling,…

If it’s Soft and Pliable, CGR has Got it Covered

Getting the proper lamination for your products can mean the difference between a good, sturdy product that is protected or one that doesn’t measure up. When you need the right lamination for your item, CGR offers the right products to fit your needs. With lamination available for products that range in size from 0.062” to…

How CGR Value-Added Services Help Your Business

At CGR Products, we offer value-added services to enhance your company and its products. Our aim is to use our top-quality services to meet your organizational needs and go beyond what you expect of us. Our CGR team offers an array of value-added services for the design, packaging, assembly, repair and distribution of your goods….

What is EMI-RFI shielding?

To understand what EMI/RFI shielding is, we must first understand what EMI/RFI is. EMI stands for electromagnetic interference and when dealing with radio frequency, it is addressed as radio-frequency interference. These interferences can cause a disturbance with electronic devices. In turn, these disturbances can degrade and limit the effectiveness of a circuit within the device….

The Many Benefits of Waterjet Cutting

Now that you better understand Kiss Cutting, it’s also important to understand when Waterjet Cutting benefit your manufacturing process. Perhaps the most important characteristic of waterjet cutting is that it can be used on materials that are sensitive to high temperatures that are common of other methods. Essentially,Waterjet Cutting is the use of a high…

Kiss Cutting

Cutting a high volume of precision, custom parts with laminate and/or adhesive takes a special kind of process. The applications for kiss cut products are numerous, including uses in the automotive, marine, HVAC, industrial, farming, electrical, medical, and military industries. You will even find kiss cut materials on escalators and elevators. It is superior in…