At CGR Products, we laminate many different materials on a daily basis. We can laminate materials up to 84″ wide and as thin as .062″. Materials can range from closed cell foam to heavy fabrics. In this series, we will look at some common ways CGR Products offers laminating services. Heat Platen Laminating This type…

Gap Fillers for Acoustical and Ingress Protection

Elastomeric gap fillers come in many shapes and sizes, from open cell foam used for acoustical management, to closed cell sponge used for sealing outside elements. In this article, we will discuss three types of gap fillers that CGR Products manufactures on a daily basis. Open Cell Polyurethane Open cell polyurethane is a great low…

Noise, Vibration, and Harshness (NVH): What You Need to Know

Guest Author: Technicon Acoustics Noise, Vibration, and Harshness (NVH) is a concern for many companies. One of our long time suppliers Technicon Acoustics has provided the below resource and also has a full version pdf available to download here. The extraneous sound and vibration are more than just an annoyance for people who work around noisy…

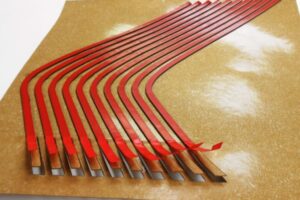

Speaker Gaskets for OEM Manufacturers

CGR Products works with many manufacturers die cutting speaker gaskets. Our gaskets are used in several markets including, marine speakers, automotive speakers, home speakers, and more. Our die cutting capabilities allow us to cut virtually any size and pattern for large volume applications. This article will describe a variety or materials and cutting methods used…

Why does my dog look me in the eye?

Why does my dog look me in the eye? He could look at my ears, my nose, my shoulders, etc.; but for whatever reason he looks into my eyes. And why does he cock his head a bit sideways when he is focused on trying to understand what I am saying? And finally, why I am…

Heat Sealed 3M™ Thinsulate™

CGR Products has been supplying various types of 3M™ Thinsulate™ materials to the automotive market for more than 10 years. The 3M™ Thinsulate™ NVH material (noise, vibration, and harshness) is used in a variety of applications across many different industries and provides a wide variety of sound absorption and dampening properties. The Advantages of 3M™ Thinsulate™…

CGR Products is Helping To Fight COVID-19

Just a few months ago, we would have never imagined we would be fighting the pandemic that we’re now facing. CGR Products is currently classified as an “essential business”. We die cut critical engineered parts that go to other essential businesses. The amount of inquires we’ve received has been both overwhelming and a blessing, including companies that…

If You Want to Influence People, Pay Close Attention to Emotions!

I have a technical behavior type and I pride myself on making fact-based decisions. As my years in the work force have progressed and my hair has moved past grey to white, I have come to realize that emotions are way more important than facts when working with others. For a person like me to…

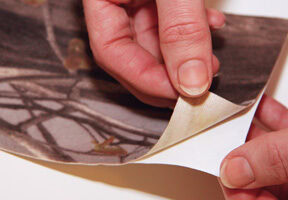

Making Things A Little Easier – Using Pull Tabs and Split Liners

Sometimes removing the liner from a die cut part can be difficult and when it comes to high volume applications, saving time can add up to dollars in the bank. One way of achieving a simple time saver is adding a pull tab or split liner to the die cut part used during assembly. In…

Benefits of Using a Vendor Managed Inventory (VMI) System

Vendor Managed Inventory (VMI) can be an effective strategy for companies looking for cost savings and a more stable supply chain. In this post, we will outline the benefits of VMI as well as the services that CGR Products provides with these programs. What is VMI? VMI is a program where the supplier manages your…

Running an Effective Meeting

Do you want your credibility to skyrocket? Learn how to run great meetings! I was recently attending a social gathering and a gentleman that served on a committee where I was the chair over 10 plus years ago came up to me and introduced me to his wife as the guy who ran the best…

CGR Products News Release

CGR Products News Release: Growth Leads to a 30,000 sq ft Expansion and New High Volume Manufacturing Machinery Click Here to read the full news release.

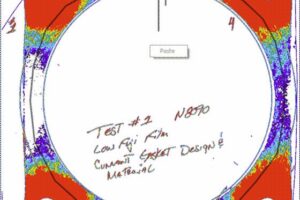

To Fuji or not to Fuji Test your Gaskets, That is the Question

Many variables can affect gasket sealing such as internal pressure, temperature, gasket design, and flange load. Sometimes it is necessary to dig a little deeper into the actual sealing picture when a difficult or critical sealing situation is encountered. In this article, we will explore a process we call “Fuji Testing”. How Fuji Testing Works…

Material of the Month: Felt

CGR Products stocks a large variety of materials for a wide range of applications. Flexible rubber sheeting, adhesive solutions, and fiber materials are just a few of our specialty options. Our Material of the Month series spotlights some of our favorite materials and their unique applications. This month, we’re discussing Felt. What is Felt? Felt…

Making a Decision

Over my career, I have had the opportunity to experience many decisions being made, a nice way to say I’m getting old. I have seen good ones and bad ones and I have made good ones and bad ones. Ultimately, over 90% of the value any person is to any organization is directly related to…