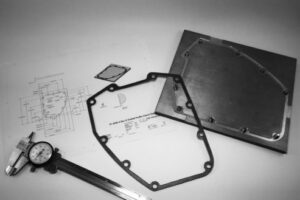

CGR Products is renowned for its commitment to quality, expertise, and innovation in the realm of gaskets, seals, and custom fabricated sealing solutions. Choosing CGR Products as your gasket provider can be pivotal for various industries and applications. Here’s why sourcing gaskets from CGR is so crucial: Unparalleled Expertise CGR Products boasts extensive expertise in…

Heat Sealed 3M™ Thinsulate™

CGR Products has been supplying various types of 3M™ Thinsulate™ materials to the automotive market for more than 10 years. The 3M™ Thinsulate™ NVH material (noise, vibration, and harshness) is used in a variety of applications across many different industries and provides a wide variety of sound absorption and dampening properties. The Advantages of 3M™ Thinsulate™…

3M and Tesla Make Good Partners

Tesla Motors creates some of the world’s most sought after vehicles. These are premium electric vehicles that have become very popular among car enthusiasts. They do not operate with a lot of moving parts. Instead, these cars basically run by a bank of batteries. 3M is a national company known for producing items such as…

3M to Increase R&D Spending

It is no mistake that 3M is one of the most successful American-born companies. Formerly known as the Minnesota Mining and Manufacturing Company, 3M now employs 88,000 people worldwide with about $30 billion in annual sales. The manufacturing giant makes more than 55,000 products such as adhesives, laminates, medical supplies, car accessories & cleaning supplies,…