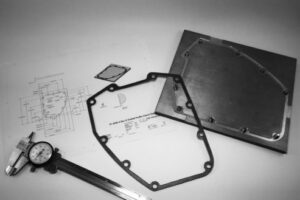

CGR Products is renowned for its commitment to quality, expertise, and innovation in the realm of gaskets, seals, and custom fabricated sealing solutions. Choosing CGR Products as your gasket provider can be pivotal for various industries and applications. Here’s why sourcing gaskets from CGR is so crucial: Unparalleled Expertise CGR Products boasts extensive expertise in…

Speaker Gaskets for OEM Manufacturers

CGR Products works with many manufacturers die cutting speaker gaskets. Our gaskets are used in several markets including, marine speakers, automotive speakers, home speakers, and more. Our die cutting capabilities allow us to cut virtually any size and pattern for large volume applications. This article will describe a variety or materials and cutting methods used…

CGR Products is Helping To Fight COVID-19

Just a few months ago, we would have never imagined we would be fighting the pandemic that we’re now facing. CGR Products is currently classified as an “essential business”. We die cut critical engineered parts that go to other essential businesses. The amount of inquires we’ve received has been both overwhelming and a blessing, including companies that…

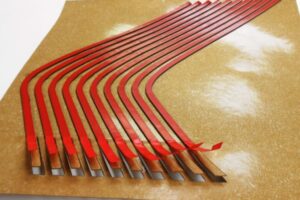

Making Things A Little Easier – Using Pull Tabs and Split Liners

Sometimes removing the liner from a die cut part can be difficult and when it comes to high volume applications, saving time can add up to dollars in the bank. One way of achieving a simple time saver is adding a pull tab or split liner to the die cut part used during assembly. In…