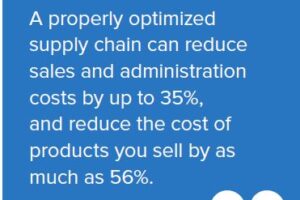

For original equipment manufacturers (OEMs), the stress of product design and manufacturing often overshadows the maintenance of a lean supply chain. Supply chain optimization is an initiative that always seems attractive, but it can be difficult to pinpoint just where to start. According to a recent TMG-IMG study, OEM supply chain management and optimization can…

The Many Benefits of Waterjet Cutting

Now that you better understand Kiss Cutting, it’s also important to understand when Waterjet Cutting benefit your manufacturing process. Perhaps the most important characteristic of waterjet cutting is that it can be used on materials that are sensitive to high temperatures that are common of other methods. Essentially,Waterjet Cutting is the use of a high…

3M to Increase R&D Spending

It is no mistake that 3M is one of the most successful American-born companies. Formerly known as the Minnesota Mining and Manufacturing Company, 3M now employs 88,000 people worldwide with about $30 billion in annual sales. The manufacturing giant makes more than 55,000 products such as adhesives, laminates, medical supplies, car accessories & cleaning supplies,…