Elastomeric gap fillers come in many shapes and sizes, from open cell foam used for acoustical management, to closed cell sponge used for sealing outside elements. In this article, we will discuss three types of gap fillers that CGR Products manufactures on a daily basis.

Open Cell Polyurethane

Open cell polyurethane is a great low cost material as a gap filler when sealing out water is not applicable. Open cell foam is made up of cells that are intentionally left open, which results in foam that is softer and more flexible. Its composition allows air and moisture to pass through so that when condensation takes place, the foam dries and doesn’t hold the moisture.

Open cell polyurethane works well for items such as bulldozers, excavators, generators, and other heavy equipment that have engines that generate a significant amount of noise. Polyurethane foam gap fillers can help reduce engine noise and other acoustical noises when water ingress is not an issue.

Open cell polyurethane from CGR Products is available with or without adhesive on one side. This material can be die cut into any shape used for a specific area or supplied in roll form. Thickness typically ranges from .125″ to 1.25″. We utilize an acrylic adhesive on our polyurethane foam for optimal long-term, durable applications.

Closed Cell Foam

Closed cell foam is made of cells that are fully closed and packed tightly together. This results in foam that is more rigid and stable than open cell foam. Closed cell foam can block air movement and water ingress. Due to the cell composition, closed cell foam is typically much denser than open cell foam.

Closed cell foam rubber can fill large voids and gaps, and also has cushioning properties to help lessen impact between two substrates. Closed cell foam is perfect for sealing gaps and helps reduce ingress, whereas open cell foam offers more flexibility. Additionally, closed cell foam is ideal for outdoor applications because it resists weathering, UV rays, and fungi.

At CGR Products, we offer a variety of adhesive options for closed cell foam gap fillers. From economical “aid in assembly” applications to higher performance permanent bonding applications. We can die cut these fillers into individual parts or they can be supplied in continuous rolls. We skive our thickness in house to accommodate our customers exact specifications.

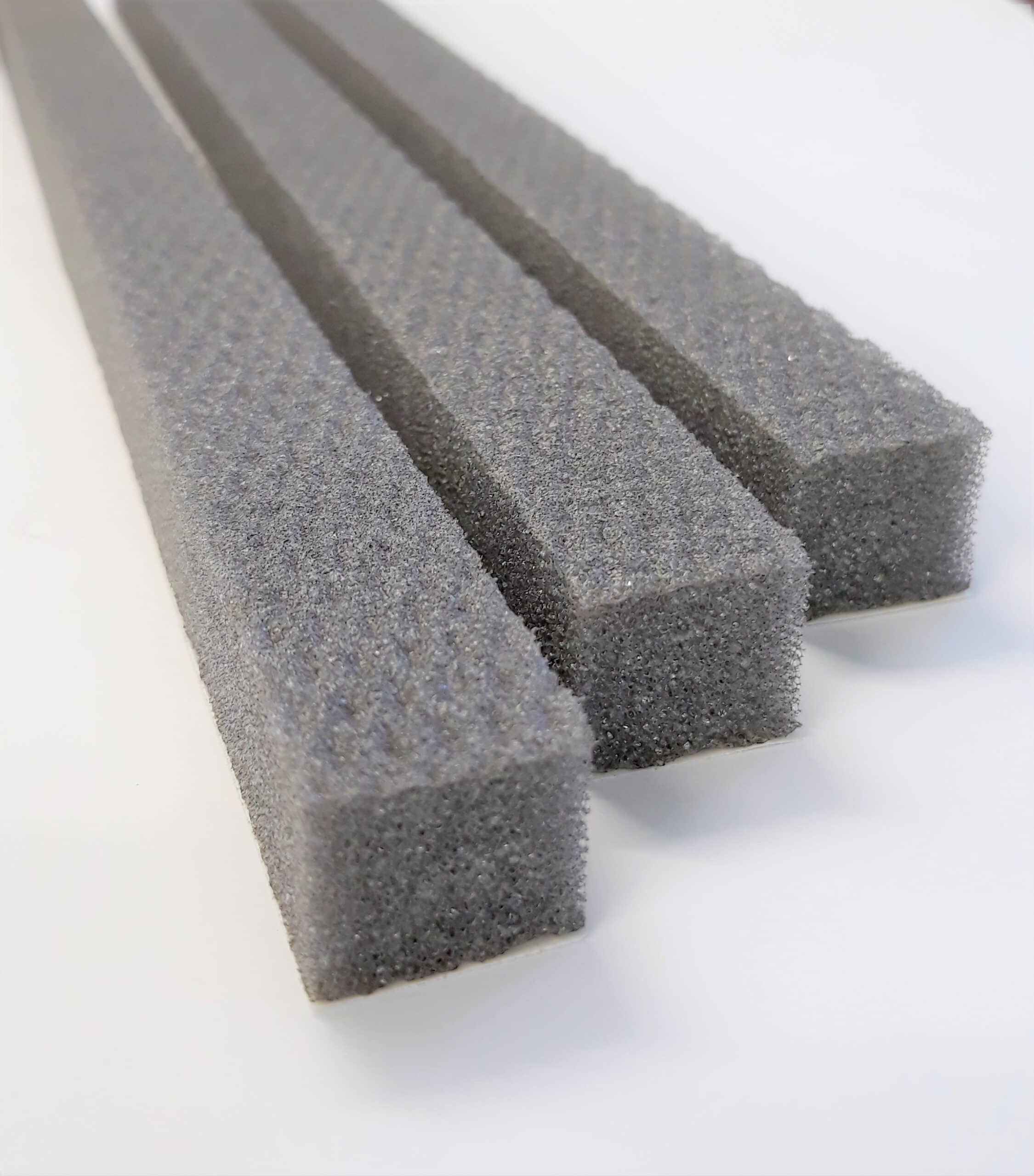

Crushed Semi-Closed Cell Foam

Crushed semi-closed foam is great for filling uneven gaps and sealing out acoustics, dust, heat, and air. Semi-closed cell foam is a soft, flexible foam. It has good UV resistance and good resistance to ozone and weathering, making it an ideal material for both indoor and outdoor use. This soft, compressible closed-cell foam, can fill various types of gaps, impede heat, water, sound, and vibration, offering a solution for various uneven types of gap filler applications. Semi-closed cell materials combine the flexibility of open cell materials with the excellent sealing capabilities of closed cell foams.

As with our closed cell foams, CGR Products offer a variety of adhesive options for semi-closed cell foam gap fillers. We offer die cutting, and various types of fabrication, such as layering and bonding different types of foams. An example of a layered gap filler is a closed cell foam on the bottom for rigidity and support, bonded with a crushed foam on the top for compression and uneven surfaces. Crushed semi-closed cell gap fillers can be die cut to meet specific sizes or supplied in roll form.

Learn More

Consider CGR Products when you are developing gap fillers for sound and ingress protection. With over 170,000 square feet of manufacturing and warehouse space and over 100 top-quality machines, CGR serves a diverse range of clients, including those in the heavy equipment industry. To learn more about our capabilities visit our Die Cutting pages or visit our Open and Closed Cell Foam pages to view a portfolio of the different types of foam we work with.