Adhesive bonding is often required for projects in many applications and industries.

With various types of bonds available to meet virtually any need, it’s important to know how to pinpoint the best option for your unique project.

When discussing your application with a bonding products manufacturer, you will be presented with a series of questions in order to narrow down adhesive options. Being able to anticipate these preliminary questions and having a clear understanding of your needs will help ensure that your project runs as smoothly and cost efficiently as possible.

Below, CGR Products takes a look at three common questions you may be asked during the adhesive selection process.

What types of stress will be exerted on the adhesive?

Just as different plastics perform differently when subjected to various stresses, so do adhesives. The same stresses that will be applied to your part as a whole will also be applied to the adhesive joining your part, so it’s imperative to consider how potential stresses may affect your part.

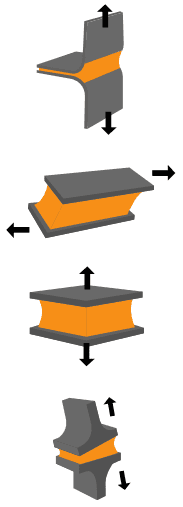

- Peel stress — This occurs when forces pull the edges of bonded components in opposite directions.

- Shear stress — Shear stress occurs when two bonded components are moved in separate directions along the parallel plane of the adhesive.

- Tensile stress — This is the result of components being pulled in opposite directions perpendicularly to the plane of the adhesive.

- Cleavage stress — This occurs when stress is applied to components along one edge of a bonded component in a prying motion.

What environmental resistance is necessary?

Environmental factors impact material adhesives differently than they do structural materials, such as plastics or metals.

You most likely put a great deal of thought into the environmental conditions your part is likely to encounter and how those conditions will affect the performance of your part as a whole, but have you considered how those same conditions might affect your part’s adhesive bonding? UV rays, moisture, chemicals, and extreme temperatures can all affect adhesives’ strength and durability.

Is the bond temporary or permanent?

Another factor that must be considered is whether your bond will be temporary or permanent. Permanent bonds are usually helpful to replace mechanical fasteners. This can eliminate welding or drilling holes which can damage the substrate. Permanent bonds can equally distribute forces over the bonded area.

While low-tack material adhesives have undeniably shorter lifespans than high-tack permanent adhesives, many varieties can remain effective for quite a long time. There are also many applications — such as removable or changeable components within parts or systems — in which low-tack adhesives can actually perform more effectively than high-tack adhesives.

Learn More

For more than 50 years, CGR Products has been a leading supplier of reliable, high-quality adhesive products, including acrylic adhesives, rubber adhesives, and other material bonding solutions.

To read more about how to best prepare for your meeting with an adhesives manufacturer, download our free “Adhesive Materials Checklist” today.