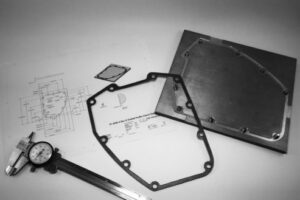

CGR Products is renowned for its commitment to quality, expertise, and innovation in the realm of gaskets, seals, and custom fabricated sealing solutions. Choosing CGR Products as your gasket provider can be pivotal for various industries and applications. Here’s why sourcing gaskets from CGR is so crucial: Unparalleled Expertise CGR Products boasts extensive expertise in…

Component Foams Specifically Engineered for Automakers

Guest Author: Isabell Wright, Armacell . For most major car makers, all parts must be made from materials that are on their approved source list. It’s a competitive business and only the best suppliers with a proven track record of quality, new technology, on-time delivery and service will make the cut. Once a material has…

Speaker Gaskets for OEM Manufacturers

CGR Products works with many manufacturers die cutting speaker gaskets. Our gaskets are used in several markets including, marine speakers, automotive speakers, home speakers, and more. Our die cutting capabilities allow us to cut virtually any size and pattern for large volume applications. This article will describe a variety or materials and cutting methods used…