At CGR Products, we field a lot of questions about the differences between open and closed cell foam. To address these inquiries, we’ll be comparing the two types of foam and outlining the unique benefits and properties of each.

When deciding on a material for your specific project, it’s important to understand which kind of foam will best serve your application and meet your unique requirements. The benefits of each type of foam can differ depending on your specific industry, so it’s important to fully assess each option before moving forward.

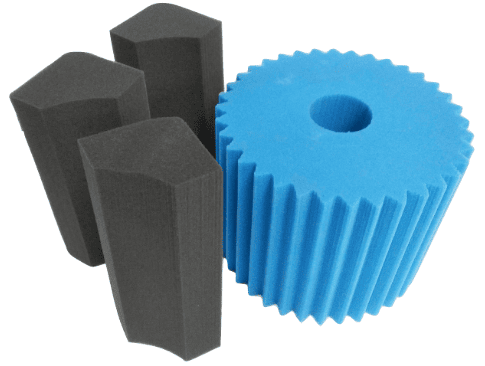

Open Cell Foam

Open cell foam is a rubber-like product made by incorporating an inflating agent, such as sodium bicarbonate, into the rubber compound; this agent gives off a gas, which expands the rubber during vulcanization.

Foam is usually classified as “open cell” when more than half of its cells are open. Common open cell materials include reticulated foam, polyurethane foam, and open cell rubber.

Some open cell foam is unique in that it operates more like a spring, easily returning to its original state after compression thanks to the unrestricted air movement and chemical makeup. Soft and breathable, open cell foam is generally more flexible and can more easily conform to sealing applications than closed cell foam. Open cell foam can also be manufactured at both high and low densities. It is less durable than closed cell options, however.

Reticulated foam is usually classified by PPI (pores per inch). 10 PPI foam would have large cell structures and allow the most flow, while 80 PPI foam would have very small cells and be more restrictive.

Closed Cell Foam

Closed cell foam is defined as a cell totally enclosed by its walls and hence not interconnecting with other cells. Closed cell foam is usually made by subjecting a rubber compound to a gas, such as nitrogen, under high pressure. This type of foam may also be made by incorporating gas-forming materials into the compound.

Closed cell foam offers a wide variety of material and density options. EPDM, Neoprene, EPDM/CR/SBR, and PVC/NBR are a few common types of closed cell foams, which can range in densities from 6 lb/ft3 (soft) to 19 lb/ft3 (hard).

This type of material is ideal for sealing as it effectively reduces liquid and gas flow. Closed cell foam is also ideal for industries in which liquid resistance is critical, such as marine, HVAC, and automotive.

Learn More

CGR carries several types of open and closed cell materials, including neoprene, PVC/NBR, silicone, microcellular urethane foam (PORON®), and polyurethane foam, and we keep a wide variety in stock to reduce lead times. We can also convert foam materials as needed for your application and will work with your team to find a solution that works for your project, no matter how complex.

To learn more about foam materials and identify which type is right for your next project, download our comprehensive Chemical Compatibility Guide.